Summary Highlights

- Yes, you can apply new epoxy over existing commercial epoxy floors — provided you perform proper prep and testing.

- Recoating saves time and cost while improving durability, safety, and aesthetics.

- Proper surface prep and adhesion testing ensure long-term performance.

- AZ Garage Floors offers customized epoxy and polyaspartic recoating solutions for any commercial space.

When it comes to maintaining commercial or industrial flooring, one of the most common questions we get at AZ Garage Floors is: Can you install new epoxy over existing epoxy floors? The short answer is yes — you can recoat, but only if the existing floor meets certain conditions. As a company with over 30 years of experience in commercial epoxy and polyaspartic flooring systems across Arizona, we’ve learned that success depends on proper assessment, surface prep, and product compatibility.

What Determines If an Existing Epoxy Floor Can Be Recoated?

Before we apply new epoxy or polyaspartic coatings, we perform a thorough floor evaluation. Not all existing coatings are suitable for direct recoating. Here’s what we look for:

- Adhesion and Integrity: If the old epoxy is peeling, flaking, or bubbling, it must be removed. The new system can’t adhere to unstable layers.

- Surface Contamination: Oils, chemicals, or cleaning residues can compromise adhesion. We mechanically grind or shot-blast the surface to ensure a clean, porous profile.

- Moisture Levels: Excessive vapor transmission from the concrete slab can cause delamination. We test moisture vapor emission rates (MVER) before applying any new resin system.

- Type of Existing Coating: Some older epoxies or acrylic sealers aren’t compatible with modern commercial-grade epoxy or polyaspartic coatings. In those cases, we may recommend complete removal and reinstallation.

Once the floor passes inspection, we can proceed with epoxy resurfacing or polyaspartic recoating, depending on your facility’s needs.

When Does It Make Sense to Recoat Instead of Replace?

Recoating an existing commercial epoxy floor can be a cost-effective and time-saving solution, especially for facilities that can’t afford extended shutdowns. At AZ Garage Floors, we often recommend resurfacing when the base concrete is structurally sound, the existing epoxy layer is largely intact, and the goal is to refresh the floor’s appearance or improve its slip resistance. Recoating allows businesses to maintain operational continuity while restoring the floor’s durability and visual appeal without the cost or disruption of a complete replacement.

We use fast-curing polyaspartic coatings that allow floors to return to light service within just 24–48 hours, making them ideal for busy environments like warehouses, automotive service bays, showrooms, and retail spaces that can’t close for extended periods. This approach not only reduces downtime but also delivers a seamless, high-performance surface that withstands daily wear and tear, keeping your business running smoothly.

How Do We Prepare Old Epoxy Floors for a New Coating?

Proper surface preparation is the most crucial step in achieving a successful epoxy recoating. Our commercial epoxy installers use industrial-grade equipment and proven methods to ensure a strong mechanical bond between the existing surface and the new coating. This process begins with diamond grinding or shot blasting to remove the old gloss, dirt, and any weak surface layers—exposing a clean, profiled surface ideal for adhesion. During this stage, many clients also ask if waterproofing is necessary under the epoxy coating, and we explain that moisture control plays a major role in long-term adhesion and prevents issues like bubbling or delamination. We also perform crack and joint repairs to prevent reflective cracking from transferring through the new coating and thoroughly clean the surface to remove all dust and residue, ensuring maximum bond strength.

Before applying the new epoxy or polyaspartic system, we conduct adhesion testing through sample patches to verify performance under real-world conditions. Depending on the environment, we may incorporate anti-slip aggregates for safety, epoxy mortar layers for added durability in high-impact zones, or polyaspartic topcoats to enhance chemical and UV resistance. For facilities with elevated moisture conditions, we address whether waterproofing is necessary under the epoxy coating and install moisture-mitigating primers when required. This detailed preparation process ensures every recoated floor meets the same high-performance standards as a brand-new installation—delivering long-term durability, safety, and a professional finish.

What Are the Benefits of Recoating Commercial Epoxy Floors?

Refreshing your commercial flooring with a new epoxy or polyaspartic system offers multiple advantages:

- Extended Lifespan: Recoating reinforces the existing system, preventing costly replacement.

- Improved Safety: Slip-resistant textures and compliant finishes enhance worker safety.

- Enhanced Aesthetic Appeal: A clean, seamless finish elevates your brand image — ideal for retail or automotive showrooms.

- Reduced Maintenance: Seamless epoxy floors are easy to clean and resistant to spills, oils, and heavy wear.

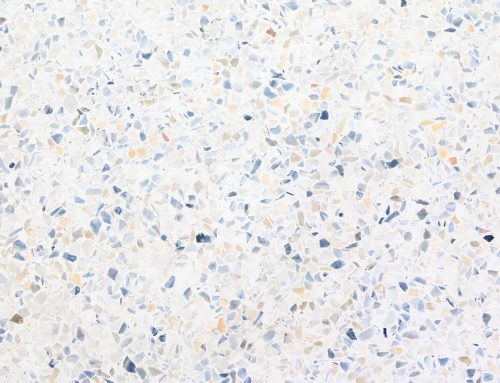

We tailor every system for performance — from epoxy mortar in high-traffic warehouses to decorative flake or solid-color polyaspartic finishes for showrooms and lobbies.

Which Coating Is Best for Your Commercial Recoat — Epoxy or Polyaspartic?

Both epoxy and polyaspartic coatings deliver outstanding durability, but the best option depends on your facility’s needs and how the floor is used daily. Epoxy mortar systems are an excellent choice for environments that experience heavy machinery, high-impact activity, or constant foot and vehicle traffic—such as warehouses and manufacturing facilities. These systems provide exceptional load-bearing strength and abrasion resistance, ensuring the floor holds up under pressure. On the other hand, polyaspartic coatings are ideal for businesses that can’t afford extended downtime. They cure quickly, are UV-stable, and maintain their color and gloss even in areas exposed to sunlight or chemical contact.

For many facilities, a hybrid system offers the best of both worlds—combining the structural strength of epoxy with the fast-curing and UV-resistant properties of polyaspartic topcoats. This approach ensures both performance and efficiency, giving you a floor that’s tough, attractive, and long-lasting. At AZ Garage Floors, we design and install coating systems customized to your operational environment, ensuring your floors not only look professional but also perform at the same high level your business demands.

What Is the Long-Term Value of Recoating Instead of Replacement?

Recoating costs less upfront and delivers strong long-term ROI. Because epoxy and polyaspartic systems bond directly to the existing coating, the process uses less material and labor while extending floor life by years. For facility managers, that means fewer shutdowns, lower maintenance budgets, and consistent performance even in high-traffic industrial settings. Our maintenance plans also include periodic inspections and topcoat refreshes, so your investment continues to look and perform like new.

Renew Your Commercial Epoxy Floor – Call Us Today

If your facility’s floor has lost its shine but still has a solid foundation, we can help you determine whether recoating is the best option. Our team at AZ Garage Floors specializes in commercial epoxy, polyaspartic, and mortar systems for all industries — from warehouses and airplane hangars to retail stores and healthcare facilities. Call us today at (602) 254-3363 to schedule your on-site floor assessment and discover how we can restore your epoxy floor’s performance and appearance with minimal downtime.

FAQs About Commercial Epoxy Floor Coatings

About AZ Garage Floors

AZ Garage Floors is a family-owned concrete coating company serving Buckeye, Surprise, Peoria, Avondale, and Phoenix. With decades of combined experience and hundreds of residential and commercial installations, AZ Garage Floors offers a full spectrum of garage floor coatings — from decorative residential systems (solid color epoxy, Granitex chip systems, metallic epoxy) to industrial commercial solutions (epoxy mortar, heavy-duty polyaspartic, chemical-resistant and anti-slip systems). The company utilizes commercial-grade 2-part resin products, thorough substrate preparation, and performance-based specifications to ensure longevity and safety. AZ Garage Floors offers residential warranty options and commercial warranty terms tailored to the project’s scale and usage.