Summary Highlights

- The most common epoxy failures come from poor prep, improper mixing ratios, and ignoring moisture conditions during installation.

- Environmental factors like heat, humidity, and ventilation directly affect curing, adhesion, and long-term durability in commercial floor coatings.

- Thickness inconsistencies and lack of routine maintenance accelerate wear in high-traffic zones, reducing slip resistance and chemical protection.

- Professional installers prevent these risks with proper surface profiling, application checks, and tailored commercial-grade systems for heavy-use environments.

Commercial and industrial epoxy floor coatings are engineered for durability, chemical resistance, and heavy traffic. But even the best materials can fail if misapplied. Understanding common epoxy application mistakes can save facility managers costly repairs, downtime, and maintenance headaches. At AZ Garage Floors, we’ve seen it all over 30 years of commercial installations—from warehouses and service bays to retail showrooms and airplane hangars. In this guide, we’ll share the most frequent pitfalls and how professional preparation and application prevent them.

Why Is Proper Surface Preparation Essential Before Epoxy Application?

One of the most common mistakes in commercial and industrial epoxy installation is skipping or underestimating concrete surface preparation. Failing to profile the concrete or address moisture issues properly can lead to adhesion problems, peeling, or blistering. Essential steps such as testing for moisture vapor emission rates, performing diamond grinding or shot blasting to create a proper surface profile, and addressing cracks or joint detailing ensure the coating bonds correctly and performs as intended.

Without thorough surface preparation, even high-quality epoxy or polyaspartic coatings will struggle to adhere, compromising durability and longevity. Properly prepared surfaces create a seamless, non-porous finish that not only enhances resistance to impacts, abrasions, and chemical exposure but also makes cleaning and maintenance much easier, supporting long-term performance in demanding commercial and industrial environments.

How Does Improper Mixing Affect Epoxy Performance?

Another frequent mistake is mixing the epoxy resin and hardener incorrectly, which can compromise the coating’s performance. This can result in:

- Uneven curing

- Sticky or soft areas

- Bubbling or blisters on the finished surface

Fast-cure polyaspartic systems are susceptible to temperature and mixing ratios. Following manufacturer instructions carefully ensures uniform coverage, long-term chemical resistance, and a smooth, high-performance finish. Failing to monitor these factors can lead to uneven curing, reduced adhesion, or premature wear. Proper handling and application are critical to achieving the durability and appearance expected in commercial and industrial environments.

What Role Do Timing and Environmental Conditions Play in Application?

Temperature, humidity, and ventilation can make or break a commercial epoxy installation. Applying coatings in extreme heat, cold, or high moisture conditions can create:

- Cracking

- Bubbling

- Uneven textures

Fast-cure polyaspartic systems are susceptible to temperature and mixing ratios. Following manufacturer instructions carefully ensures uniform coverage, long-term chemical resistance, and a smooth, high-performance finish. Failing to monitor these factors can lead to uneven curing, reduced adhesion, or premature wear. Proper handling and application are critical to achieving the durability and appearance expected in commercial and industrial environments.

Why Are Thickness and Coating Uniformity Critical?

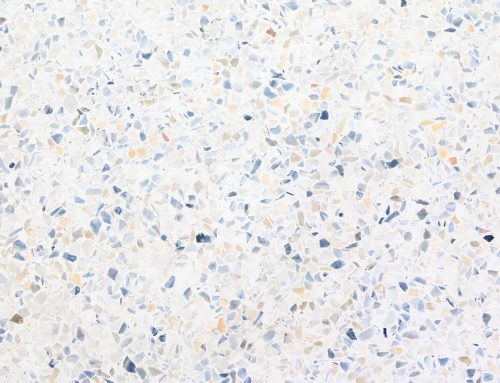

Applying epoxy too thin or too thick is a common mistake that can compromise both durability and slip resistance. Uneven coverage often leads to premature wear in high-traffic areas, such as forklift lanes in warehouses, automotive service bays, and retail showrooms. Using industrial-grade coatings, such as epoxy mortar or reinforced polyaspartic systems, helps ensure the correct thickness and uniformity, providing superior abrasion resistance, impact protection, and chemical durability. Properly applied coatings maintain performance over time while keeping commercial and industrial floors safe and reliable.

How Do Maintenance Mistakes Impact Longevity?

Even a perfectly applied floor can fail if proper maintenance isn’t followed. Using harsh chemicals that degrade the coating, skipping periodic topcoat reapplications in high-wear lanes, or ignoring gouges, joint wear, and localized damage can all significantly shorten the average lifespan of commercial epoxy flooring. These avoidable issues often lead to premature failure, costly repairs, and unnecessary downtime in industrial and commercial environments.

Following scheduled cleaning protocols, adhering to maintenance SOPs, and implementing protective measures are essential for preserving the integrity and performance of your flooring. With consistent care, facility managers can keep the system operating at peak performance, extend the service life well beyond typical expectations, and maintain a safe, attractive, and cost-effective surface for years to come.

How Can Professional Installation Reduce Risk?

Many epoxy flooring mistakes occur when DIYers or untrained installers attempt work. Professional installation includes quality assurance checks for adhesion, slip resistance, and surface smoothness, ensuring the floor performs as intended under heavy traffic and chemical exposure. Installers also tailor solutions to meet the specific needs of warehouses, retail spaces, or food-grade facilities, providing the right balance of durability, safety, and aesthetic appeal.

In addition, professional installers select appropriate colors, textures, and safety features, such as anti-slip aggregates, to enhance both function and appearance. Their expertise helps minimize downtime, maintain compliance with safety codes, and deliver long-term value for your commercial or industrial flooring investment.

Prevent Common Epoxy Flooring Mistakes – Partner with Trusted Professionals

Epoxy and polyaspartic floor coatings provide unparalleled durability and professional appeal for commercial and industrial spaces—but only when applied correctly. Avoid costly errors by focusing on surface prep, proper mixing, environmental conditions, and ongoing maintenance. If you’re planning a commercial flooring project, our team at AZ Garage Floors can assess your facility, recommend the right system—epoxy mortar, polyaspartic, or decorative flake coatings—and ensure flawless installation. Call us today at (602) 254-3363 to schedule your consultation and protect your investment with professional-grade commercial floor coatings.

FAQs About Commercial Epoxy Floor Coatings

About AZ Garage Floors

AZ Garage Floors is a family-owned concrete coating company serving Buckeye, Surprise, Peoria, Avondale, and Phoenix. With decades of combined experience and hundreds of residential and commercial installations, AZ Garage Floors offers a full spectrum of garage floor coatings — from decorative residential systems (solid color epoxy, Granitex chip systems, metallic epoxy) to industrial commercial solutions (epoxy mortar, heavy-duty polyaspartic, chemical-resistant and anti-slip systems). The company utilizes commercial-grade 2-part resin products, thorough substrate preparation, and performance-based specifications to ensure longevity and safety. AZ Garage Floors offers residential warranty options and commercial warranty terms tailored to the project’s scale and usage.