Summary Highlights

- Reseal epoxy and polyaspartic floors every 1–5 years, depending on usage and environmental conditions.

- Regular resealing maintains chemical resistance, gloss, and safety compliance.

- Professional surface prep and QA testing ensure long-term adhesion and performance.

- AZ Garage Floors provides custom maintenance plans to reduce downtime and extend floor life.

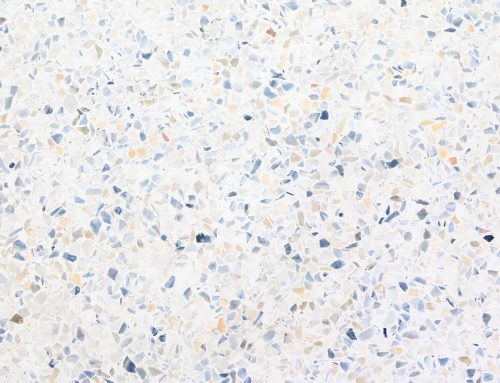

Epoxy and polyaspartic flooring systems aren’t just aesthetic—they’re a performance asset that protects your business investment. Resealing is one of the most critical aspects of long-term epoxy floor maintenance. Over time, high-traffic areas like warehouses, automotive showrooms, airplane hangars, and retail spaces experience wear from forklifts, foot traffic, and chemical exposure. Without timely resealing, your once seamless finish can lose its gloss, chemical resistance, and slip-resistant texture. A fresh topcoat not only restores the surface but also strengthens the bond between layers, preventing delamination and protecting your substrate from moisture, oils, and abrasion.

How Often Should You Reseal Commercial Epoxy Floors?

There isn’t a one-size-fits-all timeline for resealing—frequency depends on your facility’s environment, traffic volume, and cleaning practices. In general:

- Light to Moderate Use: Reseal every 3–5 years for showrooms, retail areas, and offices.

- Heavy Industrial Use: Reseal every 1–2 years, where forklifts, pallet jacks, or chemical spills are standard.

- Extreme Conditions: In manufacturing or maintenance bays, consider annual inspections and partial reseals in high-impact lanes.

At AZ Garage Floors, we conduct on-site evaluations to test your floor’s surface hardness, gloss retention, and chemical resistance before recommending a maintenance plan. Our moisture vapor emission rate (MVER) testing also ensures long-term adhesion during resealing.

What Signs Indicate It’s Time to Reseal Your Epoxy or Polyaspartic Floor?

Just as machinery needs maintenance, your commercial epoxy or polyaspartic flooring provides visible clues when it’s time to reseal. You might notice a dull or uneven sheen as the topcoat begins to lose its UV stability, or fine surface scratches and scuff marks from wheels, tools, or heavy equipment. Staining and discoloration can also appear when chemicals or cleaning agents degrade the protective surface. At the same time, a noticeable reduction in slip resistance often indicates that the textured aggregates or traction additives have worn away. These signs all indicate a coating that’s losing its ability to protect the concrete substrate beneath.

Ignoring early warning signs can lead to deeper substrate damage, including delamination, moisture intrusion, and costly structural repairs. Regular resealing restores the floor’s protective barrier, enhances chemical and abrasion resistance, and maintains the professional, high-gloss appearance your business depends on. With timely maintenance, your epoxy or polyaspartic floor continues to perform safely under pressure—delivering both long-term value and reliable durability.

What Factors Affect the Resealing Schedule for Commercial Floors?

We’ve seen firsthand how variables such as facility type and environmental exposure can alter a resealing timeline. Key factors include:

- Traffic Load: Forklifts, carts, and constant movement wear the topcoat faster.

- Chemicals and Cleaners: Solvents, oils, and detergents can erode protective layers.

- Temperature and UV Exposure: Polyaspartic coatings resist fading better but still need periodic care.

- Cleaning Routine: Harsh scrubbing pads or acids can reduce coating life.

AZ Garage Floors’ technicians help you balance these variables with epoxy, polyaspartic, or hybrid floor systems designed for your operational conditions. Our coatings maintain slip resistance, OSHA compliance, and high-traffic durability while minimizing downtime.

What Are the Steps Involved in Resealing Commercial Epoxy Floors?

A professional resealing project involves precision and preparation. Here’s how we handle it at AZ Garage Floors:

- Mechanical Surface Prep: We use diamond grinding or shot blasting to profile the floor and remove contaminants.

- Cleaning & Crack Repair: Any damaged or loose areas are filled and leveled.

- Topcoat Application: We apply a new epoxy or polyaspartic topcoat tailored to your environment—UV-stable, chemical-resistant, and fast-curing.

- Quality Assurance: Our team performs adhesion testing, gloss measurement, and slip-resistance checks before handing over documentation.

Most projects can be completed in 24–48 hours, minimizing downtime while restoring full performance.

How Can You Extend the Lifespan of a Resealed Floor?

Maintenance after resealing plays a significant role in how long your commercial epoxy or polyaspartic floor retains its durability and fresh, professional finish. Regular cleaning with neutral pH cleaners helps preserve the coating’s integrity while avoiding harsh acids or abrasives, which prevent surface etching or loss of gloss. Strategic use of protective mats or pads in high-traffic areas—such as forklift lanes, loading docks, and entryways—can minimize impact damage and abrasion over time.

To further extend the lifespan of your resealed floor, it’s best to perform quarterly inspections to catch early signs of dulling, staining, or uneven wear before they progress. Reapplying a topcoat at the first signs of coating fatigue ensures that the underlying epoxy system remains sealed and protected. At AZ Garage Floors, we provide detailed maintenance SOPs and lifecycle documentation that help facility managers monitor performance, track maintenance schedules, and stay ahead of wear patterns—ensuring lasting value and performance year after year.

Partner with AZ Garage Floors for Your Resealing Project

We don’t just apply coatings—we build long-term performance systems. Every reseal we complete is backed by decades of field expertise, premium-grade materials, and a commitment to safety and precision. Whether your business needs epoxy mortar systems for heavy industrial environments, epoxy flooring for commercial use, or polyaspartic coatings for rapid return-to-service, our team ensures every square foot is optimized for your workload, safety standards, and compliance requirements.

Let us help you protect your facility’s foundation, reduce maintenance costs, and extend the life of your commercial flooring investment. Call AZ Garage Floors today at (602) 254-3363 to schedule your free on-site consultation and inspection. Our team will evaluate your surface, create a tailored resealing plan, and help you keep your floors performing like new.

FAQs About Commercial Epoxy Floor Coatings

About AZ Garage Floors

AZ Garage Floors is a family-owned concrete coating company serving Buckeye, Surprise, Peoria, Avondale, and Phoenix. With decades of combined experience and hundreds of residential and commercial installations, AZ Garage Floors offers a full spectrum of garage floor coatings — from decorative residential systems (solid color epoxy, Granitex chip systems, metallic epoxy) to industrial commercial solutions (epoxy mortar, heavy-duty polyaspartic, chemical-resistant and anti-slip systems). The company utilizes commercial-grade 2-part resin products, thorough substrate preparation, and performance-based specifications to ensure longevity and safety. AZ Garage Floors offers residential warranty options and commercial warranty terms tailored to the project’s scale and usage.