Summary Highlights

- Real-world insight into why epoxy and polyaspartic coatings outperform traditional flooring in industrial settings.

- Detailed breakdown of how epoxy enhances safety, compliance, and cleanliness.

- Proven strategies for maximizing longevity and minimizing downtime in high-traffic areas.

- Clear overview of which industries benefit most from epoxy flooring systems.

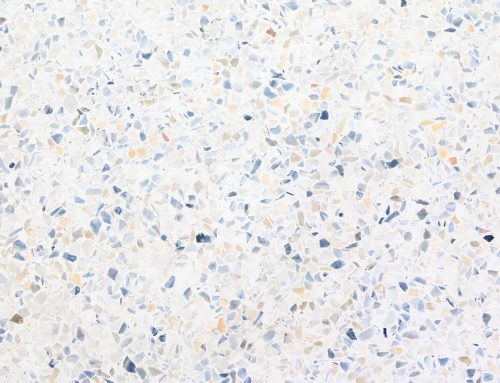

When it comes to commercial and industrial flooring, durability, safety, and performance are top priorities. Epoxy and polyaspartic floor coatings are designed to handle heavy traffic, machinery, and chemical exposure — all while maintaining a professional, long-lasting finish. These coatings create a seamless, non-porous surface that resists stains, impacts, and abrasions, making cleanup faster and maintenance easier. In addition, customizable colors, textures, and slip-resistant options allow facilities to tailor their floors to meet both functional and aesthetic requirements, ensuring a safe, efficient, and visually appealing workspace.. At AZ Garage Floors, we know your floors work as hard as your team. That’s why our epoxy and polyaspartic floor coating systems are built to withstand heavy traffic, machinery, and chemical exposure — without losing their professional finish.

What Makes Epoxy Flooring a Smart Investment for Businesses?

Epoxy flooring offers a rare combination of strength, safety, and style — all in one system. Designed from epoxy resins and hardeners that chemically bond to concrete, these coatings create a seamless, moisture-resistant surface capable of handling forklifts, pallet jacks, and daily operations in manufacturing plants or showrooms. For facilities with heavy workloads and constant foot traffic, industrial-grade epoxy floor coatings provide the durability needed to reduce wear, resist cracking, and protect against chemical damage. At AZ Garage Floors, our formulations are engineered for high-load capacity and impact resistance, ensuring long-term performance in even the most demanding environments.

How Does Epoxy Flooring Improve Safety and Compliance?

Safety is at the heart of every commercial flooring decision. Our epoxy and polyaspartic coatings are available with slip-resistant aggregates, UV-stable sealers, and VOC-compliant materials, helping businesses meet OSHA and environmental standards. We design flooring systems that actively contribute to a safer workplace — minimizing the risk of slips and falls while improving visibility through reflective, high-gloss finishes. In wet or oily areas, such as service bays or production zones, we recommend anti-slip epoxy coatings or quartz broadcast systems that combine traction with a clean, seamless look. Whether you manage a food processing facility, warehouse, or laboratory, our hygienic, non-porous epoxy systems make sanitation simple and help maintain compliance with industry regulations.

Can Epoxy Flooring Handle the Demands of Heavy Industrial Work?

Absolutely. Commercial and industrial epoxy flooring systems are engineered for durability under pressure. Our epoxy mortar floors and high-build systems distribute weight evenly, resisting abrasion and gouging from heavy machinery and vehicle traffic. In industrial settings like airplane hangars, automotive showrooms, and manufacturing plants, floors must perform without compromise. That’s why we often combine epoxy mortar layers with a polyaspartic topcoat — giving our clients a rapid return to service without sacrificing durability.

Our polyaspartic coatings cure in hours, not days, allowing businesses to resume operations quickly while gaining long-term protection from chemicals, abrasions, and UV damage.

Why Is Epoxy Flooring Better Than Traditional Concrete or Tile?

Uncoated concrete may seem durable, but it’s vulnerable to cracking, staining, and moisture intrusion, which can lead to expensive repairs and operational downtime. Tile presents its own issues—grout failure, cracked pieces, and bacteria buildup in seams. By contrast, epoxy flooring creates a seamless, protective barrier that seals your concrete surface and resists oils, solvents, and corrosive substances. Because epoxy delivers lower lifetime costs compared to tiles, it provides a far more efficient long-term flooring solution for facilities seeking durability without constant upkeep.

Unlike tile or bare concrete, epoxy-coated floors are non-porous, extremely easy to clean, and highly resistant to bacterial growth. This makes them ideal for food-grade facilities, healthcare environments, cleanrooms, and labs where sanitation and safety are critical. At AZ Garage Floors, we’ve seen businesses cut maintenance costs dramatically after upgrading to epoxy or polyaspartic systems—thanks to minimal cleaning requirements, superior performance, and exceptional longevity.

How Long Does Commercial Epoxy Flooring Last?

With proper installation and care, epoxy flooring can last 10–20 years or more — even in high-traffic commercial and industrial areas. Longevity depends on factors such as surface preparation, coating thickness, chemical exposure, and maintenance routines. We use advanced surface preparation techniques, such as diamond grinding and shot blasting, to ensure proper adhesion. Once the system is installed, we recommend routine cleaning and periodic reapplication of the topcoat in high-wear areas to maintain performance and appearance. Our team also provides maintenance plans tailored to each facility’s operational needs, helping businesses extend the lifespan of their flooring and preserve warranty coverage.

What Types of Commercial and Industrial Spaces Benefit Most from Epoxy Flooring?

Epoxy and polyaspartic systems are versatile enough to serve almost any business. We’ve installed durable flooring solutions for:

- Warehouses and fulfillment centers need abrasion-resistant epoxy mortar systems.

- Auto dealerships and service bays require chemical-resistant coatings.

- Retail showrooms and hospitality spaces that benefit from high-gloss, decorative finishes.

- Airplane hangars and industrial facilities that demand impact resistance and quick turnaround times.

Each system is customized to balance strength, aesthetics, and operational performance, giving every business a tailored flooring solution that fits its environment.

Upgrade Your Facility with Commercial Epoxy Flooring

At AZ Garage Floors, we specialize in commercial epoxy and polyaspartic coatings designed for performance, safety, and efficiency. Whether you manage a warehouse, showroom, or industrial plant, our expert team can help you choose the right system and schedule installation with minimal disruption. Call us today at (602) 254-3363 to schedule your free on-site consultation and discover how we can transform your commercial floors into durable, professional-grade surfaces that stand the test of time.

FAQs About Commercial Epoxy Floor Coatings

About AZ Garage Floors

AZ Garage Floors is a family-owned concrete coating company serving Buckeye, Surprise, Peoria, Avondale, and Phoenix. With decades of combined experience and hundreds of residential and commercial installations, AZ Garage Floors offers a full spectrum of garage floor coatings — from decorative residential systems (solid color epoxy, Granitex chip systems, metallic epoxy) to industrial commercial solutions (epoxy mortar, heavy-duty polyaspartic, chemical-resistant and anti-slip systems). The company utilizes commercial-grade 2-part resin products, thorough substrate preparation, and performance-based specifications to ensure longevity and safety. AZ Garage Floors offers residential warranty options and commercial warranty terms tailored to the project’s scale and usage.