Summary Highlights

- Tile may appear cheaper upfront, but epoxy delivers lower lifetime costs through faster installation, minimal grout maintenance, and reduced downtime.

- In commercial environments, tile is prone to chipping, cracking, and grout staining, while epoxy resists chemical spills, abrasion, moisture, and heavy equipment traffic.

- Epoxy offers seamless hygiene, slip-resistant options, brand-aligned aesthetics, and easier long-term restoration through periodic topcoats.

- For high-traffic or industrial facilities, epoxy typically offers a better ROI, greater durability, and improved operational efficiency than traditional tile flooring.

When considering a new commercial floor, cost often becomes the first question. Tile has long been a common choice for offices, retail spaces, and lobbies due to its classic appearance and perceived affordability. Epoxy and polyaspartic coatings, on the other hand, are gaining popularity in warehouses, service bays, and industrial facilities for their durability, seamless finish, and long-term value. While the initial installation price of tile may seem lower in some cases, epoxy offers reduced maintenance, chemical resistance, and a rapid return-to-service, making it the more cost-effective option over time.

How Do Installation Costs Compare Between Tile and Epoxy?

Tile installation involves significant labor, especially for patterned layouts or large commercial areas. Subfloor preparation, grout, cutting, and alignment can add both time and expense. Epoxy flooring, particularly high-build epoxy or fast-cure polyaspartic systems, requires careful surface profiling and application, but often installs faster for large, open areas. Factoring in downtime is crucial—epoxy allows rapid return to operation, whereas tile may require days to set and grout fully. While the upfront cost per square foot may appear higher for industrial-grade epoxy, the reduced labor time, minimal downtime, and elimination of grout maintenance often offset the initial expense.

What About Maintenance and Long-Term Costs?

Tile floors are prone to chipping, cracking, and grout staining in high-traffic or industrial environments. Over time, repair costs and periodic deep cleaning can significantly increase the total cost of ownership. Epoxy and polyaspartic coatings, in contrast, offer seamless, non-porous surfaces that resist chemical spills, abrasion, and moisture. Routine maintenance is simple, and occasional topcoat reapplication restores high-wear areas without replacing the entire floor. Key advantages of epoxy and polyaspartic flooring for long-term maintenance include:

- Resistance to chemical spills, moisture, and abrasive wear

- Seamless, non-porous surfaces that simplify cleaning

- Easy restoration with periodic topcoat reapplications

- Reduced repair costs compared to cracked or chipped tile

Considering these factors, commercial epoxy flooring often reduces long-term maintenance costs while extending the floor’s lifespan.

How Do Durability and Safety Factor Into Flooring Choices?

Commercial and industrial spaces demand flooring that withstands heavy equipment, forklifts, pallet jacks, and constant foot traffic. Tile can crack under impact or uneven load, while epoxy mortar and reinforced polyaspartic systems are engineered to resist abrasion, impacts, and chemical exposure. Additionally, epoxy can be customized with slip-resistant aggregates or broadcast quartz to meet OSHA-compliant safety standards. These performance characteristics make epoxy flooring a superior choice for warehouses, laboratories, automotive service bays, and manufacturing facilities where durability and safety are essential.

Can Flooring Appearance Affect Your Decision?

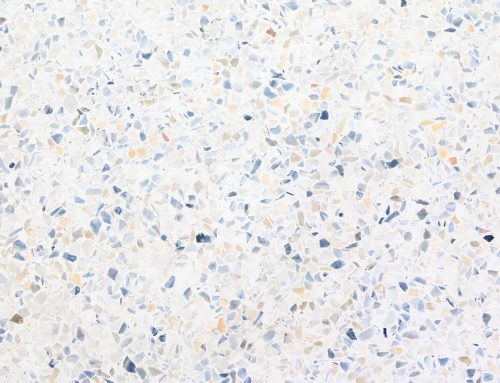

A polished tile can create a professional, clean look in lobbies or other customer-facing areas, giving a sense of sophistication and durability. However, epoxy offers far greater flexibility in aesthetics and practical design. With customizable colors, textures, and decorative flake options, epoxy floors can be tailored to complement your brand identity while providing functional benefits. Industrial epoxy floors can be finished in high-gloss, matte, or textured surfaces, allowing you to balance visual appeal with slip resistance and durability for high-traffic areas.

Beyond visual appeal, epoxy’s seamless surface prevents the accumulation of dirt, dust, and bacteria, making it easier to maintain hygiene standards in retail, medical, and food processing facilities. Unlike tile, which has grout lines that can trap contaminants and require specialized cleaning, epoxy provides a continuous, non-porous finish, reducing cleaning time and effort. For businesses seeking a combination of professional appearance, brand alignment, and practical functionality, epoxy flooring offers a versatile and long-lasting solution.

How Should Businesses Decide Between Tile and Epoxy?

Choosing between tile and epoxy requires evaluating factors such as upfront costs, downtime, long-term maintenance, durability, chemical resistance, and safety requirements. Facilities with lighter foot traffic and primarily aesthetic goals may still find tile suitable. However, in high-traffic, industrial, or high-load environments, epoxy provides superior performance and dramatically reduces lifecycle expenses. Many facility managers also consider common epoxy application mistakes when comparing options—issues like improper surface prep or incorrect mixing ratios can be avoided by hiring experienced installers, ensuring the system performs as intended.

When you look at the total cost of ownership, epoxy frequently delivers better ROI, faster installation, and safer operations for commercial and industrial applications. Its longevity, seamless design, and resistance to impact and chemicals make it the preferred solution for businesses that prioritize durability and efficiency over time.

Explore your Options and Receive a Detailed Cost Estimate – Schedule a Consultation

While tile may appear cheaper initially, epoxy flooring provides unmatched durability, chemical resistance, low maintenance, and operational efficiency. Businesses looking to optimize both performance and cost should carefully evaluate the demands of their facility. To explore your options and receive a detailed cost estimate for your commercial space, contact us at AZ Garage Floors. Call our expert installers today at (602) 254-3363 to schedule a consultation and find the flooring solution that fits your operational needs and budget.

FAQs About Commercial Epoxy Floor Coatings

About AZ Garage Floors

AZ Garage Floors is a family-owned concrete coating company serving Buckeye, Surprise, Peoria, Avondale, and Phoenix. With decades of combined experience and hundreds of residential and commercial installations, AZ Garage Floors offers a full spectrum of garage floor coatings — from decorative residential systems (solid color epoxy, Granitex chip systems, metallic epoxy) to industrial commercial solutions (epoxy mortar, heavy-duty polyaspartic, chemical-resistant and anti-slip systems). The company utilizes commercial-grade 2-part resin products, thorough substrate preparation, and performance-based specifications to ensure longevity and safety. AZ Garage Floors offers residential warranty options and commercial warranty terms tailored to the project’s scale and usage.