Summary Highlights

- Commercial epoxy flooring can last 10–20+ years with proper installation and maintenance.

- Surface preparation, coating type, and curing conditions are critical to long-term durability.

- High-traffic, chemical exposure, and industrial loads influence flooring lifespan.

- Routine maintenance and periodic topcoats extend floor life and reduce long-term costs.

Commercial epoxy flooring is renowned for its longevity, but the exact lifespan depends on several critical factors. When applied correctly to properly prepared concrete, epoxy floors can last 10 to 20 years or more in industrial and retail environments. High-traffic areas like warehouses, automotive service bays, and retail showrooms put additional stress on flooring systems. Yet, industrial-grade epoxy and polyaspartic coatings are engineered to handle heavy loads, chemical spills, and constant foot traffic. Using reinforced epoxy mortar or polyaspartic coatings ensures your floor maintains its structural integrity, color, and finish over time, while also providing a seamless, non-porous surface that resists dirt, dust, and bacterial accumulation.

Regular maintenance significantly influences longevity. Scheduled cleaning protocols, periodic topcoat reapplications in high-wear lanes, and targeted repairs for gouges or joint wear extend the life of epoxy floors far beyond initial expectations. Choosing coatings with UV- and chemical-resistant sealers adds an extra layer of durability in environments exposed to sunlight, harsh cleaning agents, or oils and solvents. When these practices are consistently followed, commercial epoxy flooring becomes a cost-effective investment, reducing long-term repair costs compared to tile, concrete, or other flooring options.

What Factors Affect the Durability of Epoxy Floors?

Several elements influence how long your commercial epoxy flooring will last. Proper surface preparation is essential for durability and adhesion. Key preparation steps include:

- Conducting moisture vapor emission rate (MVER) testing

- Diamond grinding or shot blasting to profile the concrete

- Crack remediation and joint detailing

Failing to prepare the substrate correctly can result in peeling, blistering, or premature wear, dramatically shortening the floor’s lifespan.

The type and quality of epoxy used also significantly impact longevity. Industrial-grade epoxy mortar and high-build polyaspartic systems provide superior resistance to impact, chemicals, and abrasion. Fast-curing polyaspartic coatings are ideal for facilities that cannot afford extended downtime, offering rapid return-to-service while maintaining long-term performance. Additionally, proper temperature control, accurate mixing ratios, and correct curing conditions are critical—incorrect handling can lead to uneven surfaces, reduced chemical resistance, or early wear.

How Does Traffic and Usage Influence Floor Longevity?

Traffic intensity is a key determinant of epoxy floor lifespan. Forklifts, pallet jacks, heavy machinery, and consistent foot traffic can gradually wear down coatings that are not engineered for industrial use. Using reinforced epoxy or polyaspartic systems with appropriate thicknesses ensures load-bearing performance and minimizes long-term damage. Areas exposed to chemical spills, oils, or maintenance chemicals require coatings formulated to prevent staining and degradation. High-performance commercial epoxy floors also offer safety and compliance benefits, including slip-resistant surfaces and broadcast quartz overlays that reduce accident risk. By matching the coating type to operational demands, facilities can enjoy floors that withstand daily wear while maintaining an attractive, professional appearance. In effect, floor longevity is not just about material choice—it is also a reflection of usage patterns and preventive maintenance strategies.

Can Maintenance Practices Extend Epoxy Floor Lifespan?

Absolutely. Proper maintenance is often the difference between an epoxy floor lasting 10 years versus 20, and it plays a major role in preventing premature wear of commercial epoxy coating. Routine sweeping and light cleaning are sufficient for most commercial facilities, while periodic topcoat reapplications help refresh high-wear areas without the need to replace the entire floor. It’s also essential to monitor and repair gouges, joint wear, and minor surface damage early, as neglecting these issues can accelerate surface deterioration and shorten the lifespan of the system.

Unlike tile, which can chip or grout that stains, epoxy floors are seamless and non-porous, making them easier to clean and more resistant to hidden dirt accumulation. This is especially critical for environments such as medical facilities, food processing plants, and retail showrooms where safety and sanitation standards are high. Facilities that implement a structured maintenance plan—including SOPs for cleaning, inspections, and preventive care—maximize both the longevity and return on investment of their epoxy flooring while minimizing the risk of unexpected repair costs.

How Does Epoxy Compare to Other Flooring Options?

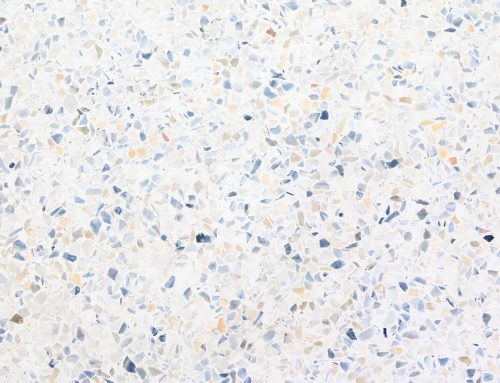

While polished tile and traditional concrete may appear cheaper upfront, they often incur higher long-term costs due to repairs, grout cleaning, and replacement cycles. Epoxy flooring, by contrast, offers a lower total cost of ownership thanks to its resistance to abrasion, chemical exposure, and heavy traffic. Additionally, epoxy can be customized with colors, textures, and decorative flake options, allowing facilities to align flooring with their brand identity while preserving safety and functionality. By evaluating long-term durability, chemical resistance, ease of maintenance, and operational demands, businesses can make informed flooring decisions. Industrial and retail facilities benefit from epoxy’s ability to maintain aesthetic appeal while delivering the performance needed in demanding environments.

What Should Businesses Consider When Choosing Epoxy Flooring?

When selecting a commercial epoxy system, consider traffic type, chemical exposure, downtime constraints, and aesthetic goals. AZ Garage Floors helps businesses specify the right system—whether epoxy mortar for heavy abrasion, polyaspartic for rapid return-to-service, or reinforced epoxy blends for long-term durability. Our team documents performance specifications, ensures QA checks, and provides maintenance guidelines to maximize floor longevity and ROI. To explore your options and get a detailed cost estimate for your facility, call our expert installers today at (602) 254-3363. We’ll provide a customized installation plan that balances durability, aesthetics, safety, and long-term performance.

FAQs About Commercial Epoxy Floor Coatings

About AZ Garage Floors

AZ Garage Floors is a family-owned concrete coating company serving Buckeye, Surprise, Peoria, Avondale, and Phoenix. With decades of combined experience and hundreds of residential and commercial installations, AZ Garage Floors offers a full spectrum of garage floor coatings — from decorative residential systems (solid color epoxy, Granitex chip systems, metallic epoxy) to industrial commercial solutions (epoxy mortar, heavy-duty polyaspartic, chemical-resistant and anti-slip systems). The company utilizes commercial-grade 2-part resin products, thorough substrate preparation, and performance-based specifications to ensure longevity and safety. AZ Garage Floors offers residential warranty options and commercial warranty terms tailored to the project’s scale and usage.