Summary Highlights

- Comparison of epoxy, polyaspartic, and hybrid flooring systems for commercial garages and facilities.

- Performance factors that determine the best floor type: durability, chemical resistance, and cure time.

- Industry-specific recommendations for warehouses, showrooms, and service bays.

- Why professional installation from AZ Garage Floors ensures lasting results and minimal downtime.

When it comes to commercial and industrial flooring, not all epoxy systems are created equal. At AZ Garage Floors, we’ve spent over 30 years perfecting epoxy and polyaspartic coating systems that perform in real-world business environments, from warehouses and showrooms to airplane hangars and service bays. The right flooring isn’t just about appearance; it’s about strength, chemical resistance, safety, and longevity.

What Makes Epoxy Flooring Ideal for Commercial Garages?

Epoxy flooring has become the go-to solution for commercial garages because of its unmatched durability and seamless finish. We use industrial-grade epoxy resins and polyaspartic coatings that withstand heavy machinery, forklifts, and constant foot traffic. These systems create a non-porous, slip-resistant surface that repels oils, chemicals, and debris while maintaining a clean, professional look. Unlike concrete or tile, epoxy floors don’t crack under pressure. Our technicians perform thorough surface preparation using diamond grinding and moisture vapor testing to ensure perfect adhesion — a critical step for longevity in commercial applications.

Which Type of Epoxy Flooring Is Best for Heavy-Duty Commercial Use?

There’s no single “best” epoxy floor — it depends on your facility’s needs. At AZ Garage Floors, we help clients choose the right system based on environment, traffic, and maintenance expectations.

- Epoxy Mortar Systems: Perfect for warehouses and industrial spaces with forklift traffic. These coatings are impact- and abrasion-resistant, forming a thick, reinforced layer that protects against gouges and chemical spills.

- Polyaspartic Coatings: For businesses that need fast turnaround, these coatings cure within hours while offering UV stability and chemical resistance — ideal for showrooms, service centers, and retail floors.

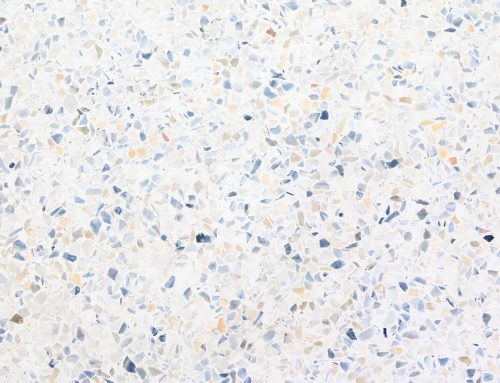

- Decorative Flake Systems: Add visual appeal and slip-resistance. These use acrylic flakes or decorative blends that mimic stone while hiding imperfections.

- Chemical-Resistant Coatings: Formulated for maintenance bays, labs, and processing areas, these epoxy blends resist solvents, acids, and oils.

Every epoxy floor we install is tailored — not just for looks, but for operational performance and safety compliance.

How Does Epoxy Compare to Polyaspartic Flooring?

Both epoxy and polyaspartic coatings are durable, but they differ in curing time and UV resistance. Epoxy systems offer greater depth and customization options, while polyaspartic floors are valued for rapid installation and long-term color stability. For commercial clients who can’t afford downtime, polyaspartic coatings offer a 24–48-hour turnaround. However, in high-impact areas like manufacturing facilities or auto shops, we often combine both systems — an epoxy base for strength and a polyaspartic topcoat for protection and shine. This hybrid approach delivers the best of both worlds: superior durability, slip resistance, and a high-gloss finish that enhances brand presentation.

How Long Does Commercial Epoxy Flooring Last?

With proper maintenance, commercial epoxy floors can last 10–20 years or more. Longevity depends on foot traffic, exposure to chemicals, and care routine. At AZ Garage Floors, we educate our clients on scheduled cleaning, resealing intervals, and minor touch-ups to preserve that showroom finish. Regular upkeep involves sweeping away debris, cleaning with mild detergents, and applying protective sealers every few years. These small efforts maintain your investment and uphold your facility’s professional image.

What Mistakes Should Be Avoided in Epoxy Floor Installation?

A poorly installed epoxy floor can lead to peeling, bubbling, or moisture-related failures. We often fix coatings applied by inexperienced contractors who skip essential steps, such as concrete moisture testing, surface profiling, or proper mixing ratios. At AZ Garage Floors, our certified installers follow a strict, step-by-step process that includes surface preparation, edge sealing, and adhesion testing. This ensures every square foot of your epoxy coating performs as intended — even in high-traffic, high-stress environments.

What Are the Key Benefits of Choosing AZ Garage Floors?

Our clients rely on us because we combine industrial performance with aesthetic versatility: our experience, 2-year commercial warranty, and a commitment to detail back every project.

- Durability Under Load: Withstands forklifts, heavy equipment, and daily wear without cracking or peeling.

- Fast Installation: Polyaspartic coatings cure quickly, minimizing business downtime.

- Safety & Compliance: Slip-resistant, chemical-proof surfaces meet OSHA and industry standards.

- Professional Appearance: Clean, reflective finishes that elevate your facility’s presentation.

Time to Upgrade Your Commercial Garage Floor – Call Us Today

If your current flooring shows cracks, stains, or wear, upgrading to epoxy or polyaspartic coatings will transform your space. A well-designed floor doesn’t just look good — it protects your team, enhances safety, and reinforces your brand’s professionalism. Many businesses also choose to incorporate decorative flakes in commercial epoxy floor systems to create a clean, polished look that’s both attractive and highly durable. At AZ Garage Floors, we specialize in custom epoxy floor coatings designed for durability, performance, and long-term value. Whether you manage a retail showroom, warehouse, or automotive facility, we can recommend the best flooring system for your environment. Call us today at (602) 254-3363 or visit azgaragefloors.com to request your free on-site consultation. Let’s build a floor that works as hard as your business.

FAQs About Commercial Epoxy Floor Coatings

About AZ Garage Floors

AZ Garage Floors is a family-owned concrete coating company serving Buckeye, Surprise, Peoria, Avondale, and Phoenix. With decades of combined experience and hundreds of residential and commercial installations, AZ Garage Floors offers a full spectrum of garage floor coatings — from decorative residential systems (solid color epoxy, Granitex chip systems, metallic epoxy) to industrial commercial solutions (epoxy mortar, heavy-duty polyaspartic, chemical-resistant and anti-slip systems). The company utilizes commercial-grade 2-part resin products, thorough substrate preparation, and performance-based specifications to ensure longevity and safety. AZ Garage Floors offers residential warranty options and commercial warranty terms tailored to the project’s scale and usage.